Part 3 - Inside Corner Radii and Depth

In Part 1, I talked about how dimensioning with common stock sizes in mind can reduce costs and save time. In Part 2, I talked about how the shape of the finished part can impact costs.

Today, I am going to talk about to lower costs by thinking about inside corner radii and depth during the design process.

Best Practice #5: To reduce cost, design your parts to have inside corner radii to be as large as possible, and don’t bother with even end mill sizes like R0.25, R0.50.

This may sound counter-intuitive, but I’ll explain it below. Note: this applies for CNC only (manual machining is opposite).

Best Practice #6: Increase the radii so that standard end mills can be used.

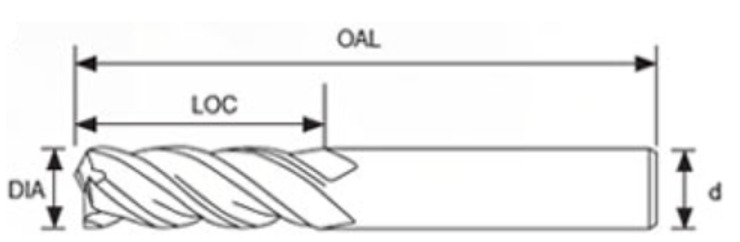

A standard end mill has a LOC (length of cut, aka flute length) of 3x its diameter. There are special end mills with longer LOC’s and extended lengths/shank undercuts, but these add cost and time to your part.

Let's look at an example:

This part has R0.3 inside corners and is 0.8” thick. A ½” end mill will be used which has a maximum LOC of 1.5”. If this part was designed with R0.25, then a 3/8” end mill would likely be used. This is still ok, as a 3/8” end mill has a LOC of over 1 inch.

Conclusion: Think about the tool that will be used, but don’t design for the same radius as that tool.

コメント